Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

ZW3D 2026 has officially launched by ZWSoft, bringing a range of updates aimed squarely at mechanical engineers, CAD users, and product teams who need a clean, integrated workflow from concept through simulation and production.

The focus this year is on precision machinery design, faster drawing generation, and native simulation capabilities.

The update is shaped by feedback from over 2,800 users. At the top of the list is a new real-thread modeling tool designed for manufacturers who need simulation-ready geometry that doesn’t take ten minutes to model by hand. ZW3D now supports detailed lead screw threads and includes a library of standardized slot features, cutting modeling time by more than 90 percent and raising fatigue life prediction accuracy.

For sheet metal, the software has improved one-click conversion from solid models, with associative updates and new features like louvers, embosses, and cutouts. This has already halved design time for consumer product enclosures in real-world use.

ZW3D 2026 also adds tools for speeding up large assembly design. Smart constraints, intelligent fasteners, and batch operations like copy-with-constraints and smart mirror all reduce the time it takes to get models simulation-ready. In one documented case, a full two-day assembly process was reduced to one hour.

For companies producing large volumes of 2D drawings, ZW3D now automates view projection and dimensioning using AI-powered templates. One engineering team producing up to 10,000 drawings a month saw a 70 percent time savings. View projection speed is also up, dropping from five minutes to one in a 150,000-part layout test.

A new IPX 2.0 engine handles data exchange across platforms. Conversion accuracy now hits over 90 percent for SolidWorks files and 85 percent for Creo, making it easier to switch or collaborate across different CAD ecosystems.

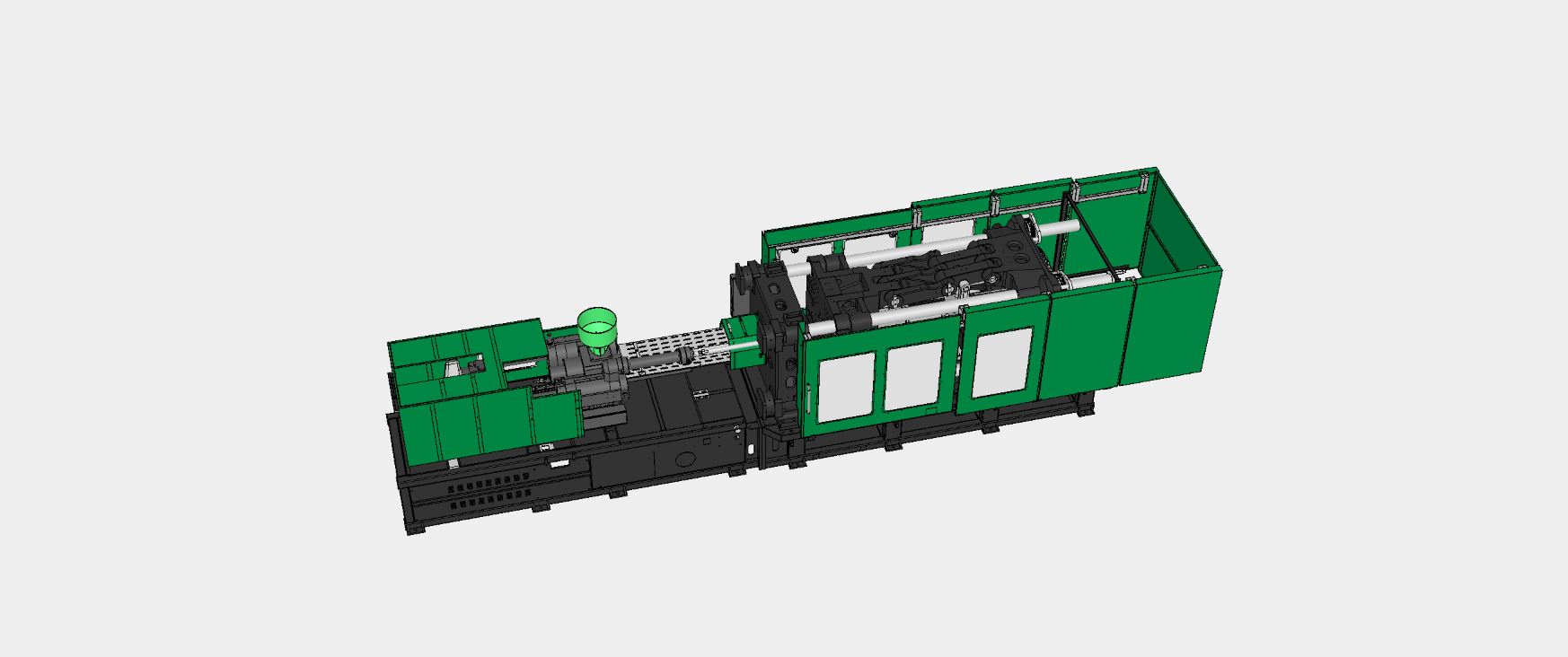

ZW3D also improves model-sync between 2D and 3D, so that edits made to 3D files update corresponding 2D drawings in real time. One injection molding project that used to require four hours of drawing edits per change now takes just three minutes.

New modules include integrated CFD simulation using Phoenics and ZWTeammate, a built-in collaboration tool for task tracking, data versioning, and controlled publishing.

ZW3D 2026 positions itself as more than just a design tool. With improvements across modeling, simulation, documentation, and data exchange, it’s becoming a complete CAx platform for teams that value speed, accuracy, and interoperability without the usual friction.

If you would like to demo the software for yourself, you can avail of your free 30-day trial at the ZW3D product page at this link.